I'm ashamed to say it's been over a year since my last post. My modelling is usually in binges, in other words I do nothing else for a while until I hit a technical or design snag or lack of funds, then leave it alone. In the intervening time I have been learning about and building a couple of valve guitar amps and I'm halfway into a wooden sailboat build. Eventually I get my modelling mojo back and dive back in.

So I now present... a totally new project, the Explorer. It's some sort of mobile planetary exploration vehicle, a travelling laboratory and living quarters. It is based on Traxxas Summit running gear mounted on an extended Revo 3.3 chassis. The inspiration has come from "Snow Cruiser" an Antarctic explorer built in 1939.

|

| Snow Cruiser 1939 |

Snow Cruiser was a roving base for a crew of 5, consisting of four 10 foot

high electrically powered and individually steerable wheels. It housed

two 150 hp diesel generators to power the electric wheel motors, as well

as living quarters, kitchen,machine shop, photo lab, communications and

storage for a years supply of food.

Yes, I know I haven't finished any of the other projects yet, don't worry I will get back to them, eventually.

All the parts were sourced from the usual place Ebay, from the many RC parts-stripping vendors who buy new kits, and break the model down into components to sell off cheaper than the pre-packaged spare parts.

I've got an older EVX2 speed control which doesn't have low voltage cutoff so I have added a Novak 2C Smart stop unit. The Summit uses two battery packs which connect in series internal to the ESC. The smart stop is wired in with one of the ESC's battery connectors, the side which provides the BEC. It means that only one of the packs is being monitored by the Smart stop, but you can assume the other pack is discharging a similar rate. Here is an extremely helpful wiring diagram courtesy of SuicideNeil from

robotwars.00server.com.

|

| Extremely helpful wiring diagram courtesy of SuicideNeil from robotwars.00server.com |

Note that the two Titan 550's are replaced with a single Titan 750 in this application. The E Revo uses a pair of standard motors whereas the Summit uses the one larger donk. The new version of the Smart Stop is self sensing so it can cope with 2c-4c packs. There is a pile of much cheaper alternatives from Hobby King which plug directly into the balance lead of the pack which is pretty simple and convenient.

This larger motor is the same size as used in many cordless drills, I have one out of an old Panasonic drill which even has a 32 pitch pinion gear mounted which mates happily with the Summit transmission.

Two aluminium angle battery trays have been attached with my usual aluminium brazing rods.

There is still some work to do on the chassis, bracing the battery trays and a micro servo mount for Hi-Lo gear changing duties. One of the other features of the Summit is remote diff locking, at this stage I think I will just leave that as a manual switch rather than getting the push rod runs sorted out for servos.

I will also need the stiffest springs I can find, the purple ones, as the body is likely to be relatively heavy. Most Rc vehicles are designed to haul around a lightweight Lexan body however in the world of RC-SCIFI it is more likely going to have to deal with a heavy hand made shell loaded with "stuff". The suspension is one of the main technical obstacles to overcome, coping with the extra weight. It has consequences for the drive line as well, but most RC vehicles are engineered for extreme speed and that comes with a degree of over engineering that will cope with greater mass at the lower speeds that these SCIFI models will run. It just means gearing down for torque, rather than up for speed.

The two speed of the Summit tranny is perfect for this.

The tyres and wheels are Proline, They are huge, 3.8" 40 series, 175mm tall, 87mm wide on 17mm Traxxas hubs.

With the chassis well on the way, I turned my attention to designing a body. I started a few rough thumbnails, when I say rough I mean really rough.

Armed with these I drew up a full size side view template on cardboard, checking against the chassis.

I used 6mm ply wood ( probably overkill but it's what I had lying around, my philosophy is use up what you have, first) for the structure. I bored and hole sawed out lightening holes wherever possible.

It was all glued up with Aliphatic wood glue which is immensely strong but slow to dry. Other less critical wooden components used a fast set pva glue. The top of the shell was skinned with 2mm plywood, again because I had a piece the right size and because the wood to wood bond is very strong.

Sections are skinned with 1mm high impact styrene sheet, which in this case happens to be black. It is more usually white, but its what my local supplier had. It is much cheaper to source this styrene sheet from a plastics supplier than buy the tiny expensive sheets in the hobby store. This model is BIG it uses a lot more materials than a 1/35 scale military diorama. The styrene is sanded to provide a rough "keyed" surface for the green Zap-a-gap superglue to bond well with the wood parts. Some judicious applications of zip kicker accelerator also help with bonding to wood. The super glue joint is very brittle and is generally not good for parts subject to shock. An RC vehicle is often subject to shock, hitting things due to mistakes or poor driving, however when there is no better method of attachment it is used. As there is a very strong and resilient wooden under structure it should work out fine here.

Styrene to Styrene bonding as well as acrylic ( perspex), I use Methylene Chloride, a known carcinogen. Unfortunately there really isn't anything better. I make sure to use it with excellent ventilation, I usually have a fan moving air past the work area and doors and windows of my shed open for fresh air flow. It is applied with a cheap nylon modelling brush from an EMA pump dispenser which I have had for years ( a very long time ago, before the advent of Computer Graphics, I was a professional model maker). The plastic container perished so I replaced it with an old poly- ethylene ink container. Poly-ethylene is not dissolved by the Methylene Chloride.

One brush has a bent end which enables getting the solvent to spots difficult to reach, undersides and the like.

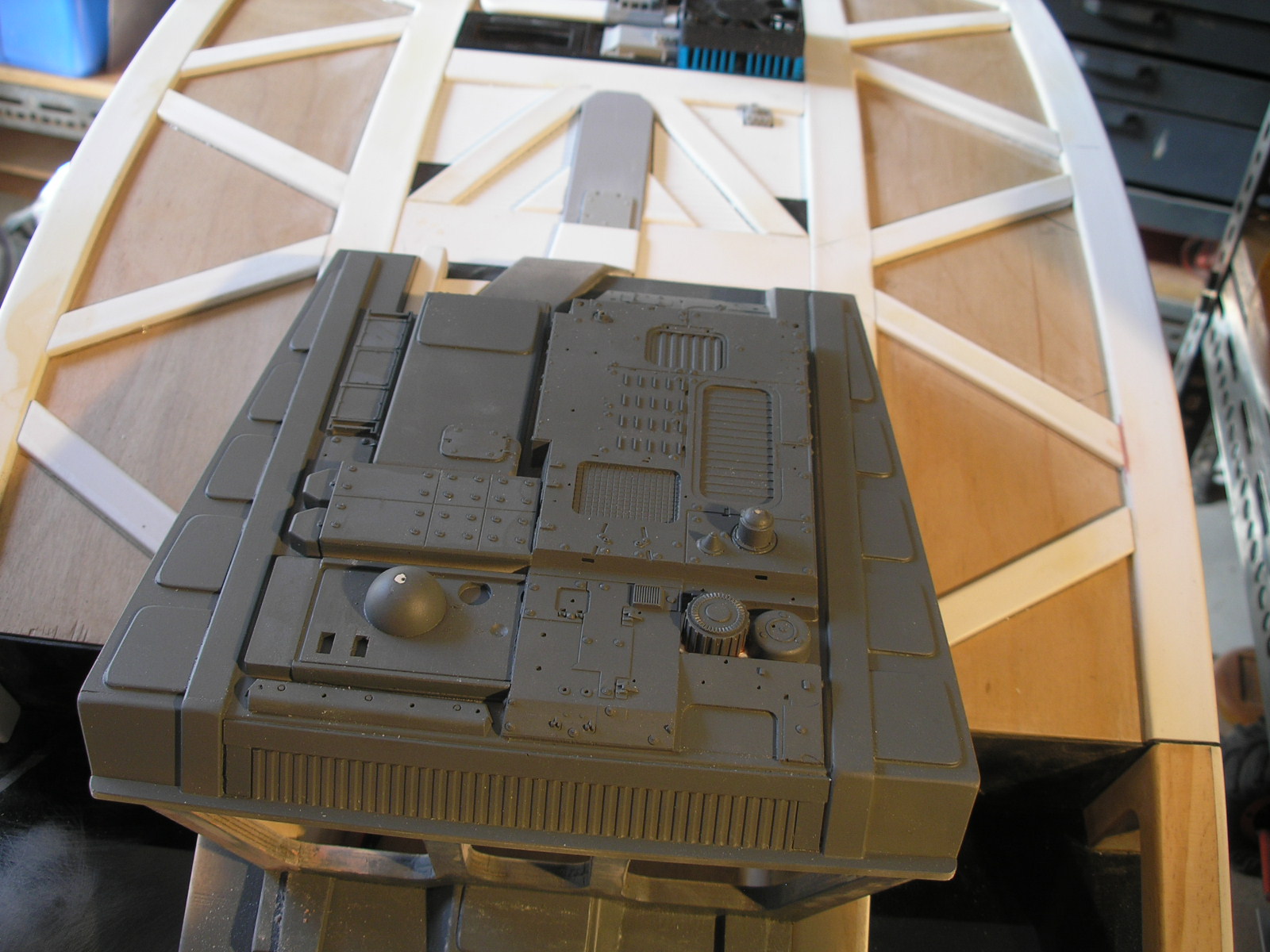

Finally here is a view of the body work so far.

I realised once I started that the original design did not allow any room for the cockpit because of the huge wheel wells. So a re-design was in order, raising the cockpit up higher and changing the scale a bit. I did another rough thumbnail to sort that out. As it turned out this is closer to the original Snow Cruiser concept.

|

| Redesigned cockpit |

|

I decided that it was about 1/12 scale so had a look in the local toy store for suitable figures and found these 1/12 Star trek figures going cheap which would suit perfectly.

The idea with the body was that it was some sort of welded truss construction, with infilled panels.

The white strips are cut from 47 X47mm 4mm thick pvc angle, used for Hardy panel (fibro cement) building corners. Again the gluing surface is roughed up with course sandpaper for the super glue to key. Pvc sticks quite well with super glue as long as it is sanded first. The PVC here is actually a type of very dense foam, so it is not quite as heavy as solid PVC sheet, being about half the weight. The foamed PVC in sheet form, is, or was, a common material used for movie miniatures. It is not effected by methylene Chloride, so it has to be bonded with PVC cement or superglue. Styrene parts have to be superglued to it.

|

| Rear detail is from an old 27mhz am radio control unit. |

|

| Test layout of some detail parts, sides from the RC control unit and a part from a Leopold model kit, plus a cpu fan which will become some sort of air conditioning unit. |

|

|

| Domes cut from PVC pipe end caps. |

|

| Inset detail from disposable camera parts... |

|

| ...which get hidden behind a grill, made from the battery door of the radio control unit. |

|

| These are the door panels, made from an old modem. More detail to be added. |

As predicted, this body is indeed quite heavy for the suspension. The current front springs are drooping to the floor at the moment, notice the block under the front holding it up. I hope the purple springs will cope. I may have to custom make some stiffer ones or get them made, we will see.

That's it for the moment. The next post will not be a year away, it will be soon, I promise.

Part 1,

Part 2,

Part 3,

Part 4,

Part 5,

Part 6.