I modified the wing supports where they meet the fuselage plate by removing some of the Foamed PVC and adding a couple of large blobs of epoxy putty where the screws will go in. Before the putty was added I spent some time sanding the Hanomag chassis end of the wing support to sit at the correct angle on the side of the fuselage. This was a fiddly job as I had to match the curve of the fuselage as well as making sure the wing supports ended up perfectly horizontal. Once I was happy with how they sat I roughed up the epoxy and the mating styrene surface, superglued them and drove in the screws. Styrene cement was then flowed around the Hanomag chassis to fuselage sides junction. I had already put a doubler of 2mm styrene around the screw holes in the fuselage side plates as reinforcement and used washers under the screw heads to spread the load. I am satisfied that the wings are now pretty strongly fixed and should survive the odd knock without coming off.

The other bonus is that now the Hanomag chassis is glued to the fuselage plates it has stiffened up the whole removable side plate and the rear tab and two cap screws are sufficient to fix the whole thing firmly in place.

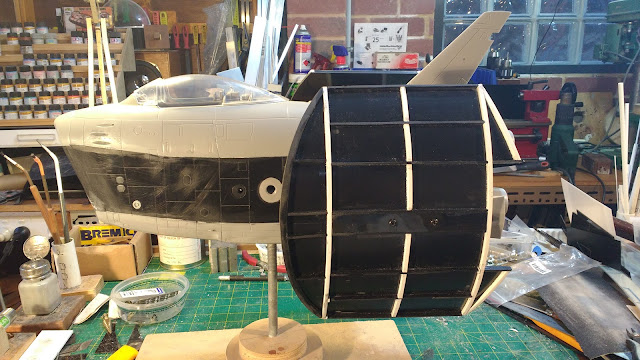

Now that all the major construction has been completed I could now assemble the main components and get a look at how it is coming along.

I am reasonably happy with the way it is looking so far. I think it has managed to remain close to what attracted me to the idea in the first place and I remain motivated to carry this on to completion.

Thanks for looking.

More soon...

No comments:

Post a Comment