In the last post about the completion of the Moon Bug Project, I promised the next project would be to complete the old New Spaceship model, however inspiration struck and I made some progress on another project that has been waiting in the wings for some years.

I still intend that will be the next project taken to completion will be the old New Spaceship model but I had an idea about how to use the giant pink Barbie Jet plane fuselage that I got from a charity shop many years ago and I just had to see if the idea would work.

I used the engines from the Barbie Jet for the Escape Pod Mk2 project back in 2016 and over the ensuing years have been trying to come up with an idea to employ the massive hull shape. Several thumbnails were drawn up, rough CG models built and I filled in the cockpit windows but it never progressed any further as none of the designs floated my boat as it were.

|

Fusleage with the windows filled in and a rough idea of where the spaceship bridge windows would be in a very early concept, ultimately rejected.

|

|

Rejected rough CG model front view.

|

|

Upside down fuselage version, also rejected.

|

|

A swiveling lifting engine idea, rejected.

|

|

Photoshopped lifting engine done over a photo of the fuselage.

|

More recently I came across an Ian McQue rough drawing on instagram that got me thinking about another way to use the bulky pink jet hull. A couple of thumbnails and many months later I had enough of a concept to motivate me to start building.

|

Ian McQue sketch Instagram post, cropped.

|

|

Looks like a giant version of the spaceship in Monty Python's Life of Brian, rejected.

|

|

Getting there but still not right.

|

|

| This is the thumbnail that got me started and suggested an approach. |

|

|

The thumbnail above was the one that got me started as I had an idea to cut the fuselage down the middle and spread it apart at the rear making more of a wedge shape. This I promptly did sawing the fuselage down the centre. I cut the nose cap off and kept that as a whole piece first.

There was still something I still didn't like about this until I wondered what would it be like if the two sides were also tilted in at the top. That idea clinched it for me as I thought it was a much more interesting shape. I attacked the two sides by holding them onto a belt sander until I removed enough styrene material to make them come together at the front so that the nose cap would still sort of fit.

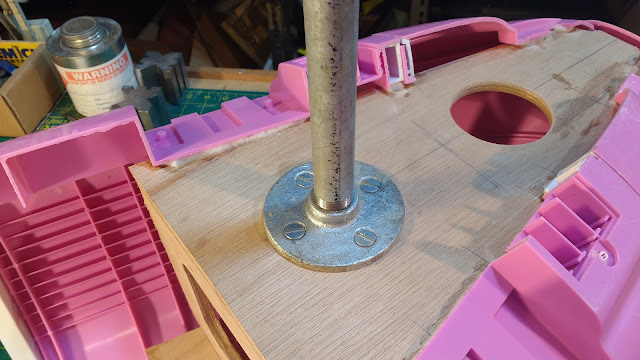

I then set about to make a simple plywood structure that would hold the two

sides together at an angle and provide a place to mount the 15mm water

pipe mounting pole flanges one top and one bottom. I find this 15mm water pipe to be a really sturdy support for these heavy models it locks in place and is easily removed if needed due to the tapered thread.

The plastic (styrene) sides were glued to the plywood using super glue and reinforced with a lot of baking soda and thin super glue.

In the photos above you can also see some 90mm PVC storm water pipe cut in half joined to a fairing made from a plastic measuring spoon also cut in half. These hard plastic spoons are a really useful shape for blisters and fairings and come in a set of four. I have used a number of them on different projects over the years, cutting off the handles and sanding the stub back to the oval shape.

I also rummaged through my stash of acrylic cups to find suitable engine bells and cut down the suitable candidates. I have a set of six Christmas wine glasses made in really thick acrylic that I am thinking of using as the lifting engines as this model is intended to be a lander with a rear cargo door.

I have another four acrylic glasses not shown in the photo which I will add at the rear. The intention is this model is to be liberally festooned with engine bells.

The next part requiring attention was the placement of the bridge/cockpit. I tried a couple of cardboard ideas along the lines of the Ian McQue sketch but it wasn't working. I then had the idea to try another spoon shape and that seemed to work so I taped the spoon to the hull and marked out a horizontal window line with a scribing tool. A piece of 2mm acrylic was heated with a heat gun until soft and pressed into the back of the spoon with a soft cloth to protect my fingers from burning to form the cockpit glass. A slot was then cutout of the spoon to make the window shape. The acrylic was then glued in from behind and a couple of small evergreen strips added as window mullions.

The next step was to build a cockpit interior as it would have to be sealed in without any means of access. Three LEDs were also added to light the cockpit a central white and a red each side for interest. The power supply will be at the usual 12 volts so after consulting an online calculator a 390 ohm resistor was added to the three leds in series at the positive end.

The scale I decided was 1/72 so three figures of that scale were obtained from my figures box and added to the mix. Most of this will hardly be visible through the tiny windows however a curious onlooker ought to be rewarded if they take the trouble to peer inside. The lighting should help to draw any viewer to take a look.

The seated pilots are on a removable base at the moment so I can get easier access for painting the interior. It will have to be finish painted before installation as access will be impossible later.

I have primed the cockpit interior and now need to paint the figures which are so tiny, something I am not looking forward to. I can't bear working on tiny models that's why I generally build so big. In this case even though the model is quite large in volume the scale is small as I am trying to convey the impression of something really huge.

Next up is to sort out the rear end and the arrangement of all the engine nozzles and their associated light sources.

Thanks for looking,

More soon...